Related resources

Report

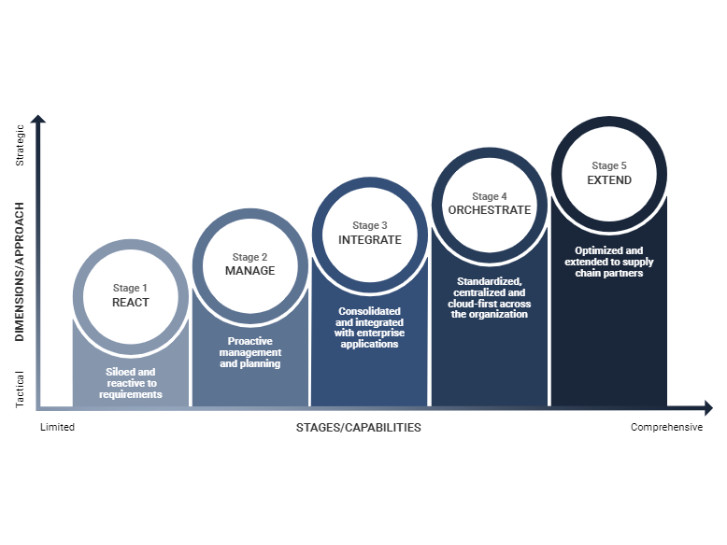

The Maturity Model for Enterprise Labeling

The Maturity Model for Enterprise Labeling offers a framework for improvement in the area of labeling throughout your...

Webinar

Five Stages of Enterprise Labeling Success ... How Do You Stack Up?

Watch the following webinar to learn how to quantify your organization’s current state of labeling along 9 key...

Blog

Are costly unknowns lurking in your supply chain?

Connected networks don’t just fix problems faster; they make supply chains stronger. When suppliers share accurate...

Webinar

Steering Through Change: Executive Perspectives on Automotive Trends

Watch this webinar as Greg MacKinnon, VP of Value Advisory at Loftware, leads a discussion with automotive industry...

Companies of all sizes continue to navigate labor constraints, inflationary pressures, and raw material outages, all of which contribute to ongoing supply chain disruption. To manage this global impact, forward-thinking businesses are looking to accelerate their digital transformation programs by investing in cutting-edge technologies, such as cloud computing, artificial intelligence, and IoT solutions, to enhance operational efficiency and resilience. The impact of cloud technology is already apparent in the business world where organizations have embraced a cloud-first strategy for many of their mission-critical business systems including enterprise resource planning (ERP), customer relationship management (CRM), and inventory management, among others. Businesses that manage inventory, customer service, and logistics in the Cloud are beginning to do the same with their labeling, ultimately gaining unmatched efficiency, scalability, and flexibility. Whether supporting remote workforces, striving for better collaboration across the enterprise, or working to improve the customer experience, these solutions help organizations meet their digital transformation goals. Companies that prioritize digital transformation now can reap the benefits of a streamlined business and intelligent supply chain to adapt their business model and deliver results while staying relevant in this shifting global landscape.

Companies of all sizes continue to navigate labor constraints, inflationary pressures, and raw material outages, all of which contribute to ongoing supply chain disruption. To manage this global impact, forward-thinking businesses are looking to accelerate their digital transformation programs by investing in cutting-edge technologies, such as cloud computing, artificial intelligence, and IoT solutions, to enhance operational efficiency and resilience. The impact of cloud technology is already apparent in the business world where organizations have embraced a cloud-first strategy for many of their mission-critical business systems including enterprise resource planning (ERP), customer relationship management (CRM), and inventory management, among others. Businesses that manage inventory, customer service, and logistics in the Cloud are beginning to do the same with their labeling, ultimately gaining unmatched efficiency, scalability, and flexibility. Whether supporting remote workforces, striving for better collaboration across the enterprise, or working to improve the customer experience, these solutions help organizations meet their digital transformation goals. Companies that prioritize digital transformation now can reap the benefits of a streamlined business and intelligent supply chain to adapt their business model and deliver results while staying relevant in this shifting global landscape.

In today’s business landscape, manual processes represent barriers to growth and scale. It’s clear that for companies still managing siloed and disconnected legacy solutions, continuity is at risk and valuable time and savings can be lost. This is especially true when it comes to labeling. However, once digitized, manual processes give way to the seamless exchange of data and allow companies to maintain existing systems and user interactions that improve overall efficiencies. Current innovative cloud-based technologies provide new levels of control and consistency, enabling business users to dynamically make changes to adapt to complex labeling variations and meet evolving customer and regulatory demands. Additionally, automating critical paths with real-time intelligent workflows clearly identifies projects that are behind schedule or at risk of running late, enabling organizations to take proactive corrective action to eliminate bottlenecks, improve time to market, and ensure compliance. The persistent struggle with manual processes across the supply chain underscores the need for a concerted effort to embrace technology and streamline operations to meet the demands of an increasingly complex and fast-paced business environment. Companies who do so will not only insulate themselves from ongoing supply chain challenges but will also set themselves up for future success.

In today’s business landscape, manual processes represent barriers to growth and scale. It’s clear that for companies still managing siloed and disconnected legacy solutions, continuity is at risk and valuable time and savings can be lost. This is especially true when it comes to labeling. However, once digitized, manual processes give way to the seamless exchange of data and allow companies to maintain existing systems and user interactions that improve overall efficiencies. Current innovative cloud-based technologies provide new levels of control and consistency, enabling business users to dynamically make changes to adapt to complex labeling variations and meet evolving customer and regulatory demands. Additionally, automating critical paths with real-time intelligent workflows clearly identifies projects that are behind schedule or at risk of running late, enabling organizations to take proactive corrective action to eliminate bottlenecks, improve time to market, and ensure compliance. The persistent struggle with manual processes across the supply chain underscores the need for a concerted effort to embrace technology and streamline operations to meet the demands of an increasingly complex and fast-paced business environment. Companies who do so will not only insulate themselves from ongoing supply chain challenges but will also set themselves up for future success.

Organizations persist in adapting their strategies to navigate the dynamics of the current global supply chain. In order to thrive in the demanding environment and maintain seamless operations, companies must be ready to explore alternative ways to optimize business processes and create new efficiencies. Corporate leaders increasingly acknowledge the direct link between supply chain health and labeling. Cloud technologies are now a key focus, enabling the expansion of labeling operations to new partners and suppliers, ensuring continuous uptime, offering device and location independence, accommodating a remote workforce, and ensuring seamless movement of parts and products without delays – both upstream and downstream. The Cloud's scalability, real-time collaboration tools, and data analytics capabilities empower businesses to adapt and respond swiftly to market changes and customer demands. By capitalizing on these benefits, businesses can achieve greater operational efficiency, customer satisfaction, and resilience in the face of ongoing disruptions.

Organizations persist in adapting their strategies to navigate the dynamics of the current global supply chain. In order to thrive in the demanding environment and maintain seamless operations, companies must be ready to explore alternative ways to optimize business processes and create new efficiencies. Corporate leaders increasingly acknowledge the direct link between supply chain health and labeling. Cloud technologies are now a key focus, enabling the expansion of labeling operations to new partners and suppliers, ensuring continuous uptime, offering device and location independence, accommodating a remote workforce, and ensuring seamless movement of parts and products without delays – both upstream and downstream. The Cloud's scalability, real-time collaboration tools, and data analytics capabilities empower businesses to adapt and respond swiftly to market changes and customer demands. By capitalizing on these benefits, businesses can achieve greater operational efficiency, customer satisfaction, and resilience in the face of ongoing disruptions.

AI technology is advancing at a blindingly fast pace, and its transformative potential will almost certainly extend to every industry in the coming years. The link between AI and Cloud is a crucial and symbiotic relationship that will play a fundamental role in the development and deployment of AI applications across the supply chain. Cloud platforms offer the infrastructure needed for AI model training and execution, along with easy access to vast datasets. Additionally, the cloud's flexibility allows AI workloads to scale up or down as required, making it a cost-efficient solution for a range of companies. It also facilitates easy collaboration and accessibility for AI solutions, while cloud providers often offer pre-built AI services, further simplifying AI development. Also, the robust security and compliance features further ensure the safe and efficient operation of AI systems. The combination of AI and the Cloud is a powerful enabler for automating complex tasks across operations, such as real-time monitoring of labeled products, managing inventory, and enhancing overall operational efficiency. Working in tandem, these technologies can analyze large datasets and inspect labels at a swift pace to ensure quicker error detection and correction. As increasingly sophisticated algorithms emerge, these advancements promise to deliver numerous benefits, fostering improved accuracy, heightened agility, and accelerated production.

AI technology is advancing at a blindingly fast pace, and its transformative potential will almost certainly extend to every industry in the coming years. The link between AI and Cloud is a crucial and symbiotic relationship that will play a fundamental role in the development and deployment of AI applications across the supply chain. Cloud platforms offer the infrastructure needed for AI model training and execution, along with easy access to vast datasets. Additionally, the cloud's flexibility allows AI workloads to scale up or down as required, making it a cost-efficient solution for a range of companies. It also facilitates easy collaboration and accessibility for AI solutions, while cloud providers often offer pre-built AI services, further simplifying AI development. Also, the robust security and compliance features further ensure the safe and efficient operation of AI systems. The combination of AI and the Cloud is a powerful enabler for automating complex tasks across operations, such as real-time monitoring of labeled products, managing inventory, and enhancing overall operational efficiency. Working in tandem, these technologies can analyze large datasets and inspect labels at a swift pace to ensure quicker error detection and correction. As increasingly sophisticated algorithms emerge, these advancements promise to deliver numerous benefits, fostering improved accuracy, heightened agility, and accelerated production.