Consumer packaged goods (CPG) manufacturers, from global leaders like Coca-Cola and Nestlé to niche brands like BarkBox and Scrub Daddy, play a crucial role in our daily lives and the economy. They support over 22 million jobs and generate $2.5 trillion in annual GDP. Yet, the CPG sector faces significant challenges including counterfeiting, rising costs, labor shortages, regulatory pressures, and shifting consumer preferences. These disrupt supply chains and pressure profitability.

To overcome these hurdles, CPG companies are adopting cloud-based solutions that streamline operations from product conception to consumer delivery. These systems improve efficiency, enhance visibility, and ensure regulatory compliance, enabling manufacturers to adapt to evolving demands while boosting profitability and resilience.

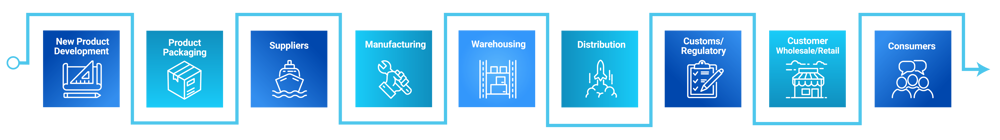

Modern CPG operations demand agile, cloud-based systems to manage the entire product lifecycle — from new product development (NPD) to manufacturing and distribution. These solutions integrate seamlessly with enterprise resource planning (ERP), customer relationship management (CRM), warehouse management (WMS), and product lifecycle management (PLM) systems, offering real-time visibility and control. To stay competitive, CPG manufacturers need an end-to-end, cloud-based solution that streamlines and automates packaging artwork and labeling processes. This solution offers:

To thrive in a dynamic and competitive market, CPG manufacturers must embrace digital transformation. Cloud-based solutions provide the agility, visibility, and efficiency needed to navigate challenges like counterfeiting, compliance, and labor shortages. By streamlining operations, these systems help companies reduce costs, accelerate innovation, and enhance customer satisfaction.

With average operating profits at just 1.2%, maintaining the status quo is unsustainable. Now is the time to innovate, optimize supply chains, and secure long-term success.