Improve consumer safety and speed time to market by minimizing errors, ensuring compliance, and managing recalls

60%

Cumberland sees 60% reduction in artwork approval times

One system

Supplyit now uses just one system to handle all daily tasks

Since installing Loftware and integrating with SAP, we have been able to expand our labeling footprint across our manufacturing facilities while successfully complying with new customer requests and additional regulatory requirements.

Tim Cukr, IT Professional, McCormick & Company

The FDA banned Red Dye No. 3 in food and ingested drugs as of January 15, 2025. Food products must be reformulated and relabeled by January 15, 2027; ingested drugs by January 18, 2028. This impacts product labels, packaging, and marketing materials - updates are essential to stay compliant.

The food and beverage industry is prioritizing transparency, sustainability, and ethical sourcing. Consumers increasingly want to know what’s in their food, where it comes from, and how it was made—driving demand for clean labels, sustainability claims, and QR codes that deliver real-time, mobile-accessible product information. These trends support both compliance and consumer trust.

Automate product identification to avoid delays and reduce mislabeling and streamlining production

Drive product identification from critical business applications such as SAP, Oracle, and regulatory databases to improve data accuracy and consistency

Streamline product identification to meet global regulations like FSMA, 21 CFR Part 11, EU 1169, and Natasha's Law and avoid recalls and fines

Provide controlled access to labeling and artwork to ensure accurate first-time product identification and prevent costly and timely relabeling

Standardize and centralize product identification to meet corporate standards and support ongoing business growth - whether through new facilities, regional expansion, or M&A

Manage short links and QR codes to share dynamic content—such as sourcing, allergens, or sustainability data—while creating mobile-first consumer experiences

It’s all right there™

Manage and scale your labeling operations with Loftware Cloud – the industry’s leading cloud labeling platform. Centralize your label management, enhance collaboration, and ensure compliance across global supply chains.

Explore Enterprise LabelingScale with Loftware CloudStreamline your packaging artwork management with automated workflows, built-in approvals, and real-time collaboration. Accelerate time-to-market and ensure regulatory compliance with Loftware Smartflow.

See Smartflow in actionLoftware’s Connected Packaging enables brands to turn every product into an intelligent touchpoint, driving consumer interaction and unlocking real-time data across the supply chain.

Raise the bar on barcodes

Eliminate human errors & reduce production downtime

Data driven labeling for regulatory compliance

Extend access to partners & suppliers

Integrated systems for agile supply chains

Centralized control for traceability & efficiency

Enhance accuracy and efficiency. Introduce transparency and accountability to your labeling and packaging review cycles, reducing risks, and accelerating time to market. This increases sales volume while lowering SG&A costs.

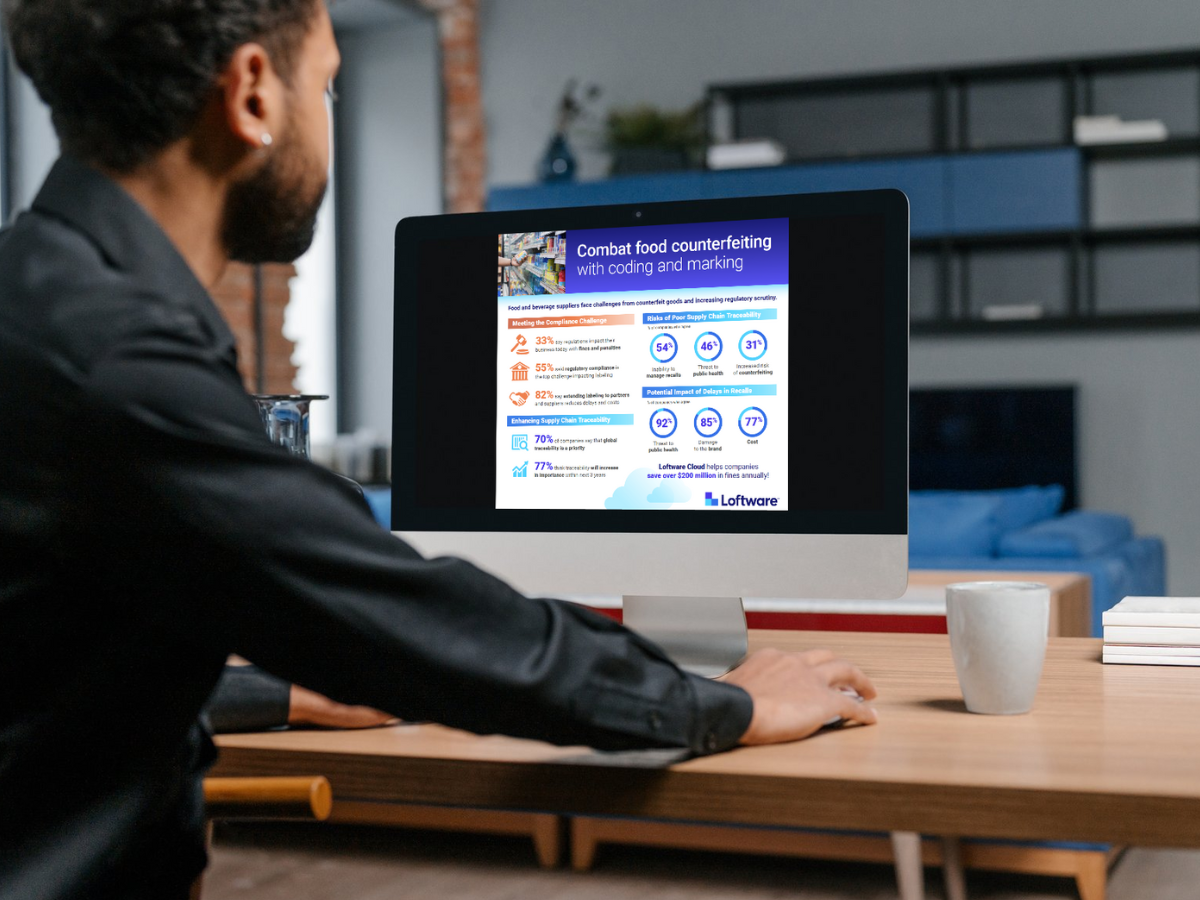

A recent survey showed that 77% of food and beverage companies think track and trace will increase in importance within the next three years. See our infographic to learn more about what else respondents said about supply chain traceability, anti-counterfeiting, and increasing regulatory scrutiny.

With Loftware Smartflow, Cumberland Packing Corp. reduced artwork approval times by 60% and increased savings by $100,000’s in reprinting costs. Loftware has been a game changer for our process.

Sara Hoskow

Brand Manager

Inside Loftware Cloud, there are a lot of capabilities that make it easier with our end users to save tons of time.

Gabriel Molina

System Analyst

Loftware has helped us centralize everything for all our departments from idea to actual first production run. It’s all in Smartflow.

Julissa Gutierrez

Marketing Services Coordinator, Lakeview Farms

At a quality and production level, we have all the data centrally managed and deployed locally, ensuring the correct data is printed and in regulatory compliance at all times.

Lucy Webb

Technical Manager

Automation is reshaping food and beverage supply chains to meet rising global demand, expected to double by 2050. Cloud technology improves forecasting, inventory, and quality while enabling strategic integration and collaboration.

Key regulations impacting manufacturers, suppliers, and distributors include:

Prohibited in food and ingested drugs due to cancer risks in animal studies.

Law to prevent foodborne illnesses with proactive FDA regulation.

FDA rules ensuring electronic records and signatures are trustworthy, reliable, and equivalent to paper.

Requires clear allergen labeling on prepackaged foods.

Improves supply chain data with barcodes and RFID standards.